Steve

Bedair's

Homemade Band Saw Page

Longview , Texas

4-2002

18" Woodcutting Band Saw

The frame is painted and all wiring is ran through the frame. No

exposed

wiring.

After all the plywood was fitted to place it was sanded and primed.

Then each piece was painted and reattached.

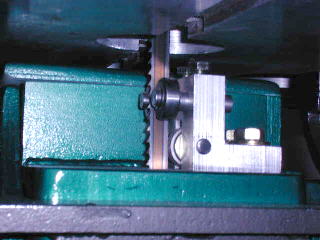

Upper ball bearing blade guides built.

The bearings are mounted on cam shafts to allow adjusting.

The upper blade guide adjust up and down on a 1" steel shaft. A 3/8"

slot was milled to keep the blade

perfectly aligned at whatever height the guide is positioned.

Lower ball bearing blade guide.

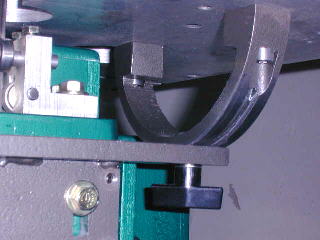

The table sits on these steel half moon shaped brackets. They were cut

from 1" thick steel plate and then

cleaned up on the Mini Mill ( very slow work )

Slots were milled to allow for the table to

move to 45 degree angle. The pic on the right shows recess milled and

drilled

to allow mounting bolt to pass through the

bracket and attach to the bottom side of the table.

Here is where the table attaching

brackets sit. The plate here was milled to the same radius as the

brackets above.

Table adjustment knob

Next Page

New

Blade guide information

Comments

/ Questions

This information is provided for

personal use only

Copyright 2000 - 2011

Steve Bedair